Understanding EUV Mask Blanks: The Foundation of Cutting-Edge Semiconductors

Introduction

In the world of semiconductors, EUV (Extreme Ultraviolet) lithography is at the forefront of manufacturing advanced chips for applications like AI, high-performance computing, and cutting-edge consumer electronics. One of the most critical components of this process is the EUV mask blank—a high-tech material used to create photomasks that enable precise chip patterning. But what are EUV mask blanks, and why are they so crucial?

What Are EUV Mask Blanks?

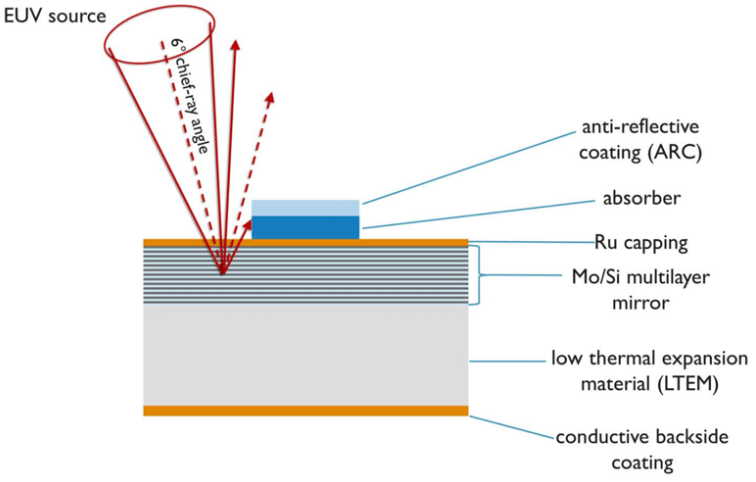

EUV mask blanks are highly specialized materials that serve as the foundation for photomasks in EUV lithography. They consist of:

Glass Substrate: Made from ultra-low expansion (ULE) glass or synthetic quartz, these substrates ensure stability and minimal distortion during the lithography process.

Multilayer Coatings: Alternating layers of molybdenum (Mo) and silicon (Si) that reflect EUV light at 13.5 nm.

Absorber Layer: A layer that blocks unwanted EUV light to define the precise patterns on chips.

The precision of these components is critical, as even microscopic defects can disrupt the patterning process and reduce chip yields.

Market Players: The Current Landscape

Two companies dominate the EUV mask blank market:

HOYA: With a market share of 60-70%, HOYA leads the global supply, thanks to its advanced technology and strong relationships with major chipmakers like TSMC and Intel.

AGC (Asahi Glass Co.): Holding 30-40% of the market, AGC is known for its expertise in glass substrates and integrated production capabilities

References: Global Info Research, GII Research

New Entrants to Watch

As the demand for EUV technology grows, new players are striving to enter this highly technical market:

Shin-Etsu Chemical: Leveraging its experience in synthetic quartz production, Shin-Etsu is developing its own EUV mask blanks to compete with the market leaders.

S&S Tech: Based in South Korea, this company is focusing on innovative solutions like advanced pellicles and High-NA EUV mask blanks to capture market share

References Shinetsu, ETNEWS : Korea IT News

Supporting Ecosystem: Suppliers and Collaborations

EUV mask blank production relies on highly specialized materials:

Glass Substrates: These are sourced from industry giants like Corning and AGC. Corning’s Extreme ULE glass is particularly valued for High-NA EUV lithography. Shin-Etsu, however, utilizes its in-house synthetic quartz substrates

Inspection Tools: Precision tools from companies like Lasertec ensure that mask blanks meet the stringent quality standards required for EUV lithography

Challenges and Future Outlook

Producing EUV mask blanks is incredibly challenging, requiring defect-free multilayer coatings and stable glass substrates. As EUV technology evolves toward High-NA systems, the requirements for mask blanks will become even more demanding, offering both opportunities and hurdles for new and established players alike.

Conclusion

EUV mask blanks are a critical, if often overlooked, element of modern semiconductor manufacturing. With dominant players like HOYA and AGC setting high standards, and ambitious entrants like Shin-Etsu and S&S Tech pushing boundaries, this market is at the heart of technological innovation. As the semiconductor industry grows, understanding these foundational technologies provides a glimpse into the future of electronics.

Further Reading

Comments

Post a Comment